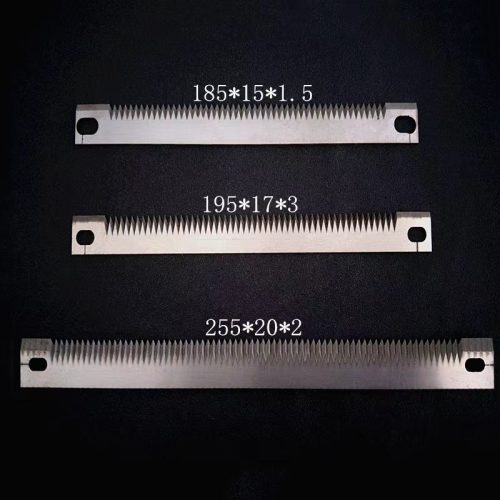

Non-Standard Recycling Blades

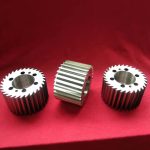

Pelletizer Rotary Cutter

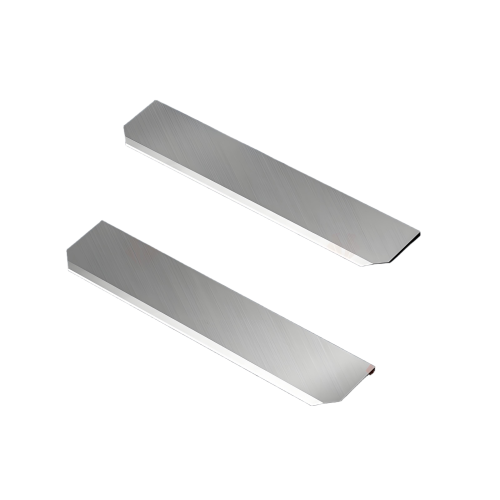

Product Benefits Increased blade durablity and reduced retooling time. Higher precision available, anti vibration and small thermal deformation. Excellent cutting quality, stable and reliable cutting performance. Forging steel to ensure blades with a long work life. Triple tempered to retain the hardness while toughness kept. Lower yearly knife consumption costs. Matched to their applications. Reward […]

Material Options: D2 (SKD-11), M2 (SKH51), Tungsten Carbide, SUS440C.

Hardness: HRC 56-60, customized as per customer requirements.

Features:

-

Triple tempering process for superior wear resistance.

-

Precise heat treatment ensures excellent cutting performance and durability.

-

Exceptional cutting longevity and wear resistance.

-

High strength and toughness with minimal thermal deformation.

-

Residual stresses are effectively eliminated to prevent unwanted or uncontrollable effects.

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing