Applications

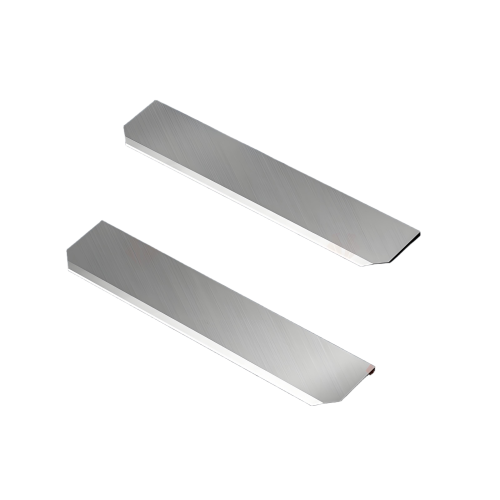

Battery‑pole foil slitting and trimming

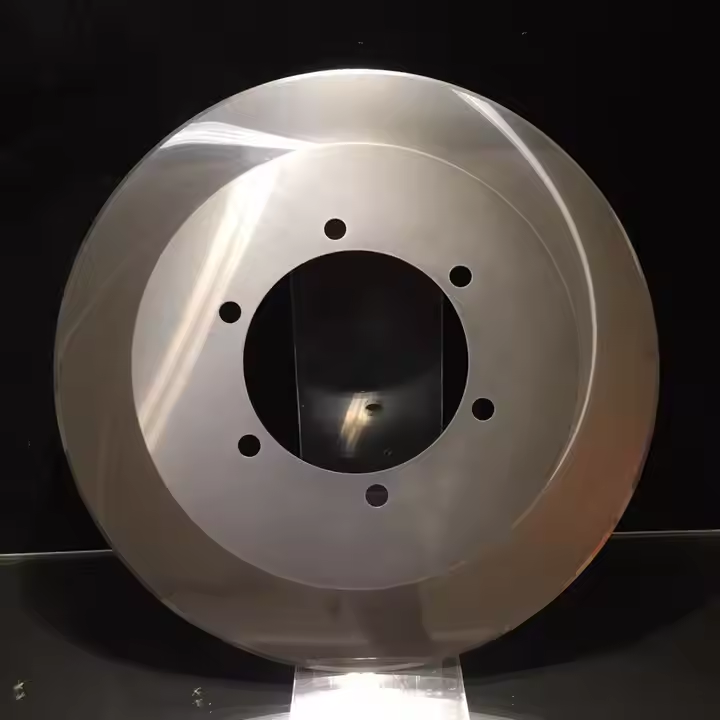

Non-Standard Round Blades

Tungsten Carbide Circular Blade

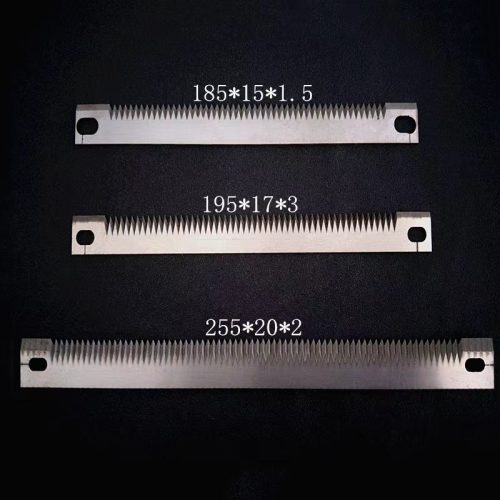

Crafted from premium materials such as 65Mn, 9CrSi, and SKD-11, our carbide slitter knives provide superior wear resistance and precision. With a hardness of 52-60 HRC, they are ideal for cutting sheet metal, paper, wood, rubber, leather, food, and plastic. Custom sizes and specifications are available, with a quick delivery time of 2-8 working days and secure packaging.

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing