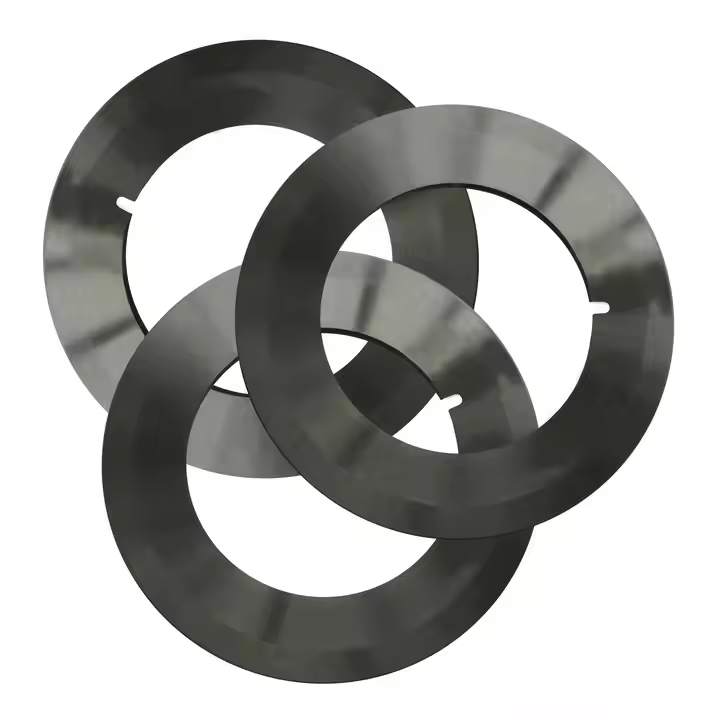

Top Slitter Knife

-

Type:Round

-

Service:Provide Customized Services

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing

Customized sizes are available, according to your drawing or sample.

Our top slitter knives are widely used in:

Whether you are slitting narrow web widths or wide web formats, we provide the right geometry and edge preparation to suit your line speed, web material and fault tolerance.

|

OD(MM)

|

HOLE(MM)

|

THINKNESS(MM)

|

MATERIAL

|

HARDNESS

|

|

60

|

20

|

1.2

|

9CRSI,SKD11/D2,

HSS,TUNGSTEN STEEL, STAINLESS STEEL, ETC.

|

55-60

|

|

68

|

46

|

1

|

||

|

65

|

40

|

1.2

|

||

|

70

|

45

|

1.2

|

||

|

75

|

45

|

1.2

|

||

|

75

|

42

|

1.2

|

||

|

64

|

38

|

1.2

|

||

|

90

|

60

|

1.2

|

||

|

98

|

66

|

1.2

|

||

|

100

|

35

|

1.2

|

||

|

100

|

66/70

|

1.2

|

||

|

105

|

70

|

1.2

|

||

|

110

|

70

|

1.2

|

||

|

118

|

80

|

1.2

|

||

|

120

|

80

|

1.2

|

||

|

130

|

80/90

|

1.2

|

||

|

140

|

90/95

|

1.2

|

||

|

150

|

80

|

2

|

||

|

180

|

80

|

1.5

|

||

|

CUSTOMIZED

|

CUSTOMIZED

|

CUSTOMIZED

|

CUSTOMIZED

|

CUSTOMIZED

|

We operate an advanced manufacturing facility with CNC grinding, surface grinding, induction hardening and laser measurement. Each knife undergoes dimensional inspection, edge finish verification and material composition testing. We stand behind our blades with a quality assurance program and global logistics support.

Do you have any questions about our products and how to use them? We have compiled the most frequently asked questions and answered them. If your question is not listed here, please contact us.

A precision blade used for slitting materials like film, foil, and paper, designed to deliver clean cuts and enhance performance in high-speed operations.

Top slitter knives are made from high-grade tool steels such as D2, 52100, and PM10V, with optional carbide or powder metallurgy for increased durability.

Yes, we offer custom sizes, thicknesses, and diameters tailored to your machine specifications and slitting requirements.

Consider material type, machine brand, desired blade material, and performance needs. Our team can provide recommendations based on your application.

Replace or resharpen when you notice a decline in cut quality, increased dust, or visible edge damage. We offer maintenance schedules for optimal performance.

Yes, we provide custom blades for machines from brands like Voith, Valmet, Bilomatic, and others. Simply share your machine model for a tailored solution.

Lifespan varies based on material and machine speed, but our high-performance knives are built for extended durability with proper maintenance.

Provide machine details, blade size, and material preferences, and request a quote through our website or contact our sales team for assistance.