Cold rolled steel, aluminium foil, clad materials

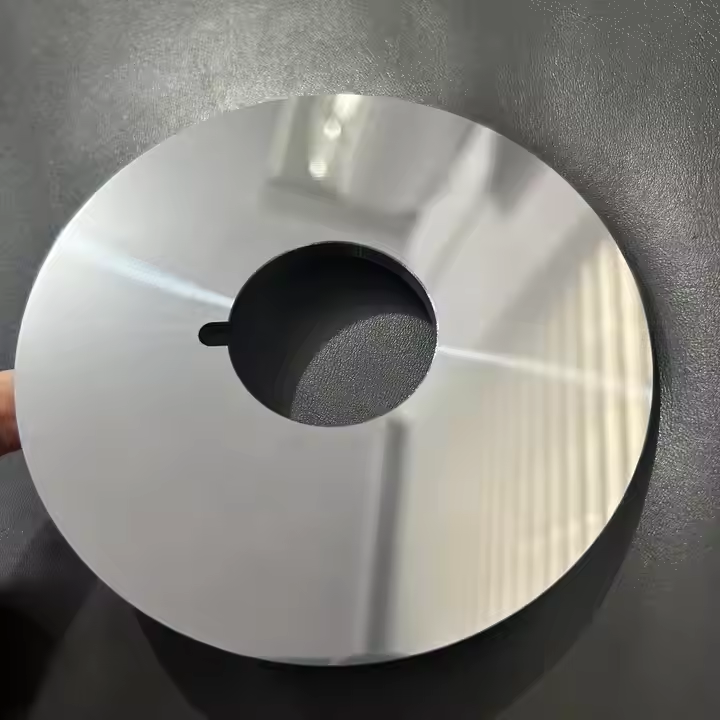

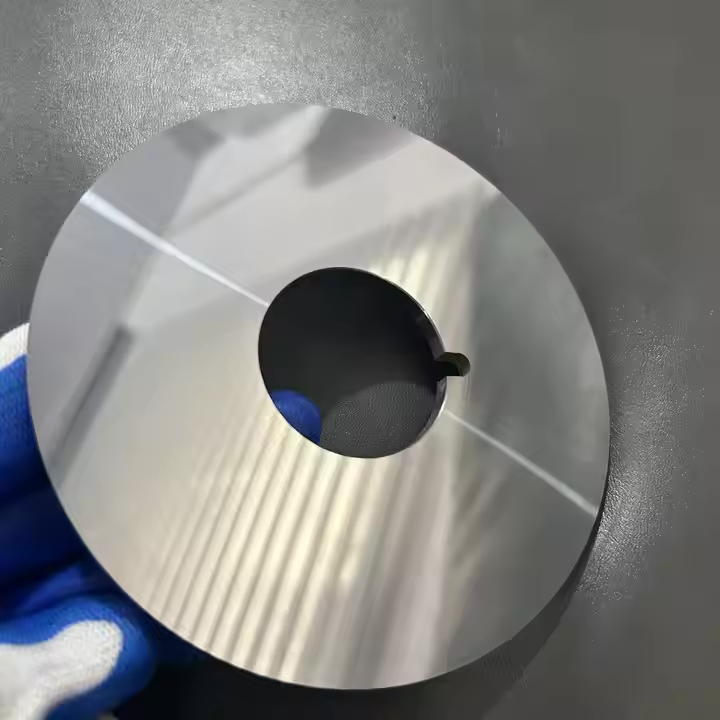

Rotary Slitter Knives

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing

Customized sizes are available, according to your drawing or sample.

|

Product name

|

Rotary Slitter Knives |

|

Scope of application

|

steel

|

|

Material

|

9Crsi/SKD-11/D2/HSS/M2/440B/420J

|

|

Hardness (HRC)

|

56/60/61/60/62/58/58

|

|

Precision (Fatness)

|

±0.01

|

|

Package

|

Plastic Bag+Foam+Carton Box

|

Fewer unscheduled stops for re‑grinding or blade changes means your slitting line runs longer — improving throughput.

Clean slit edges reduce downstream defects, edge delamination or burr generation.

Although an investment, the reduction in scrap, maintenance labour and downtime leads to lower cost per unit over time.

Custom sizes/grades means you’re not locked into standard blade options; you get exactly what your process needs.

Custom sizes/grades means you’re not locked into standard blade options; you get exactly what your process needs.

Please contact us with your slitter model, material type, required dimensions (diameter, bore, thickness), tolerance and quantity. We will provide a quotation, lead‑time and drawing proof for your approval.

After shipment, we also offer re‑grinding/refurbishment services, and technical assistance for installation, edge‑setting and performance optimization.

With decades of experience in industrial slitting solutions, our team combines manufacturing capability, quality engineering and customer‑centric service. We follow strict quality procedure to ensure each knife meets your requirements. We are committed to helping you optimize your production line — not just selling a blade.

Do you have any questions about our products and how to use them? We have compiled the most frequently asked questions and answered them. If your question is not listed here, please contact us.

Our knives are suitable for slitting metals, films, foils, non-wovens, plastics, PE boards, wood, and more.

We offer thickness tolerances as tight as ±0.02 mm, or can customize based on your requirements.

Yes, we provide customization for material, tooth-form, bevel angle, and surface finish.

Made from high-quality steels and heat-treated for durability, our knives offer long-lasting performance and reduced downtime.