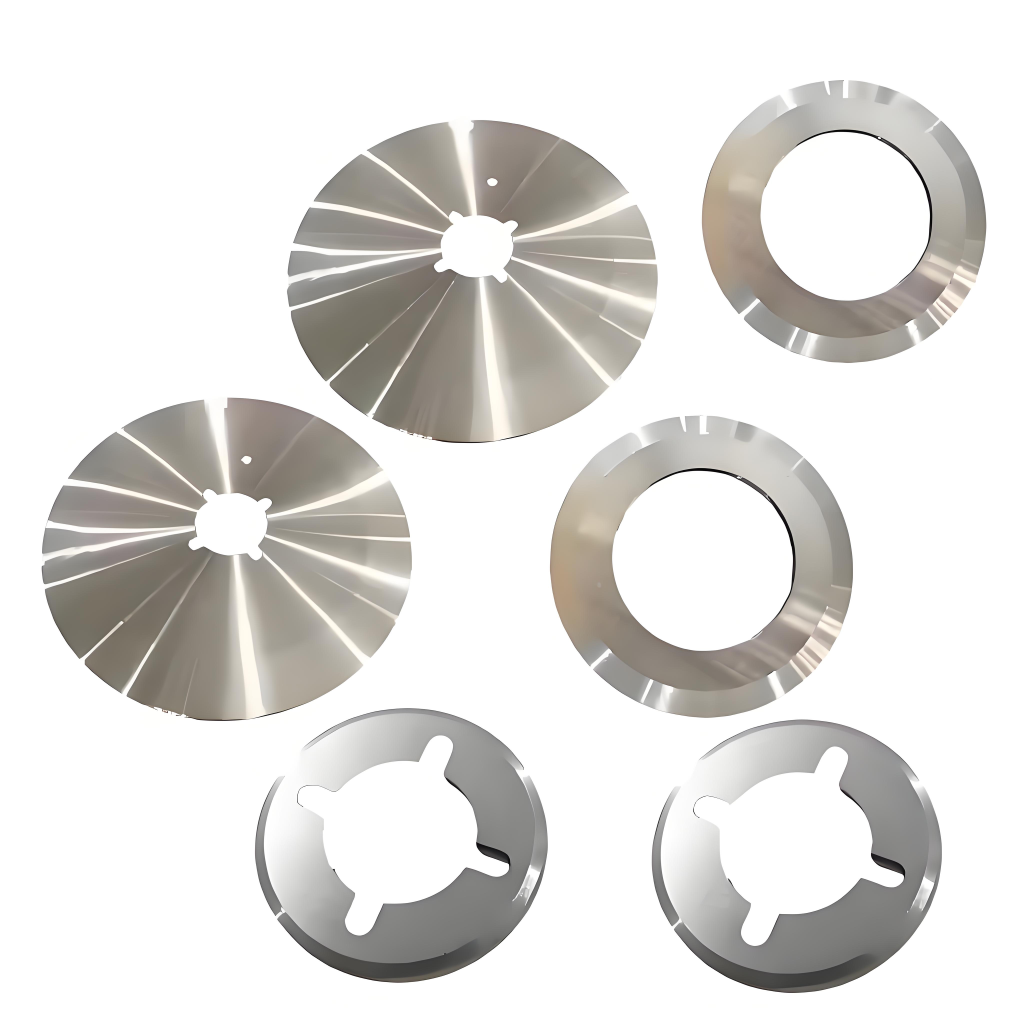

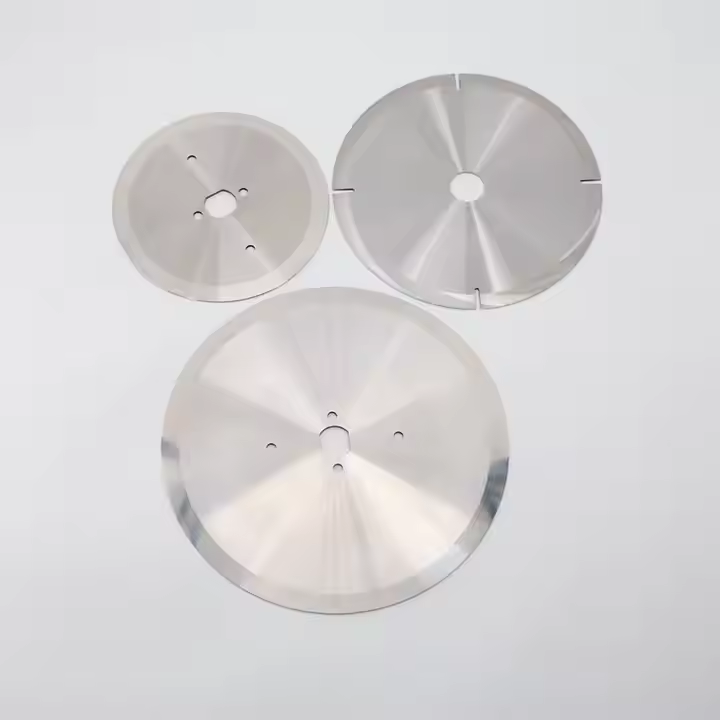

Paper Slitter Blades

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing

Customized sizes are available, according to your drawing or sample.

In paper converting and roll slitting applications, “paper slitter blades” refer to the top and bottom knives that split large parent rolls into narrower widths. These blades must maintain sharp edges under high speed, high load conditions to ensure consistent width and clean cut edges.

There are two common profiles: Flat blades and dished (concave) blades. According to industry best practice, flat blades suit high‑speed, heavy‑duty paper slitting; dished blades excel in lighter web or film applications.

Material selection also matters: From high‑carbon tool steel to carbide‑tip options depending on abrasion, web speed and service life requirements.

| The Product Name | Paper Slitter Blades |

|---|---|

| Meterial | 9CrSi SKD - 11 Cr12MoV 3Cr13 W6Mo5Cr4V2 ETC |

| The Shape Of | Can Be Customized By Customers |

| The Time Of Delivery | 3 - 10 Workdays |

| Application Industry | Metal Rubber Paper Wood Plastic Package Printing Food Leather Industry |

At YISHI we offer full customisation of paper slitter blades:

By investing in high‑quality slitter blades you:

To maintain peak performance of your slitter blades:

These practices are outlined by industry experts for longer blade life and safer operation.

Do you have any questions about our products and how to use them? We have compiled the most frequently asked questions and answered them. If your question is not listed here, please contact us.

The correct size depends on roll diameter, machine design, and web speed. Provide your machine specs and we can recommend the optimum blade.

Yes – we offer blanks, custom sharpening and re‑grinding services for ongoing maintenance.

Typical lead time for standard custom blades is [X] weeks; expedited options are available for critical operations.