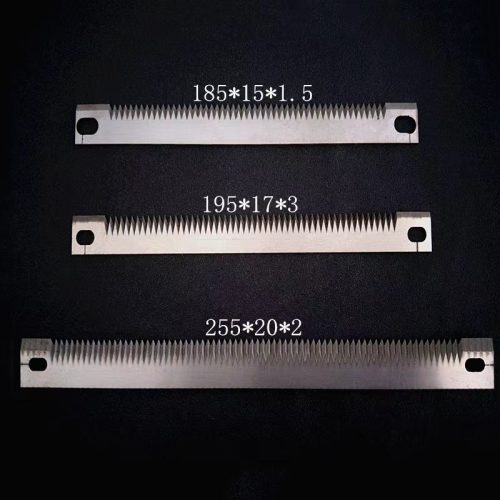

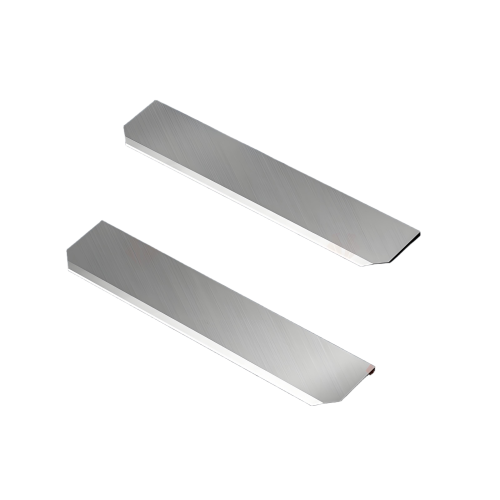

Non-Standard Film Slitting Blades

3 Hole Razor Blades

Perfect for cutting pearl film, diffusion film, optical film, water-soluble film, and more, the Tungsten Steel Three-Hole Blade ensures a long service life with a burr-free edge, offering reliable, precise performance.

Customized sizes are available, according to your drawing or sample.

- Fully Custom

- Expedited Production Processing