For pouch, sachet, and flow-wrap lines that require consistent cut length, clean separation, and stable end quality.

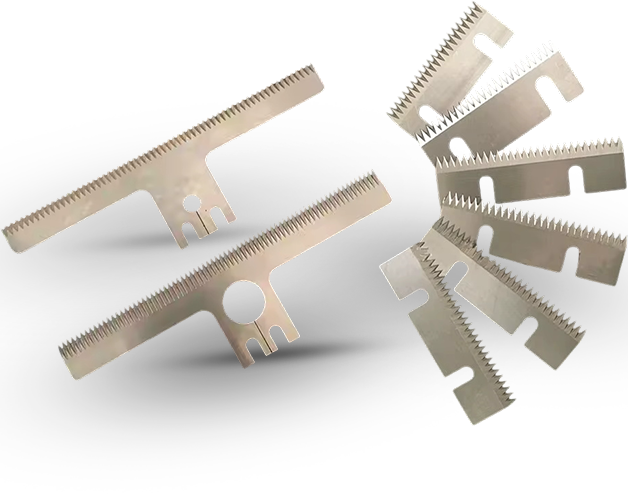

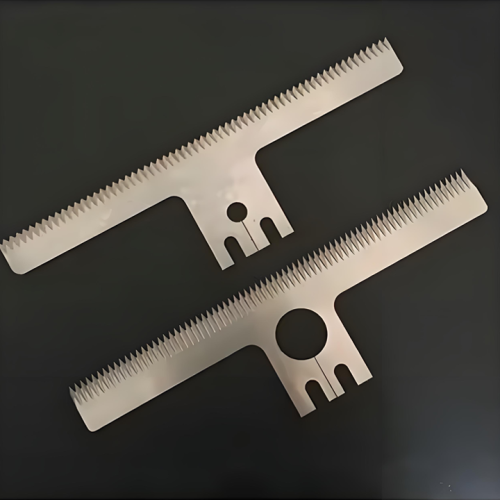

Packaging Machine Knives We Manufacture

Packaging machine knives for film, paper, and flexible materials—blade material, edge style, and surface finish matched to reduce burrs, control tearing, and support stable cutting at production speeds.