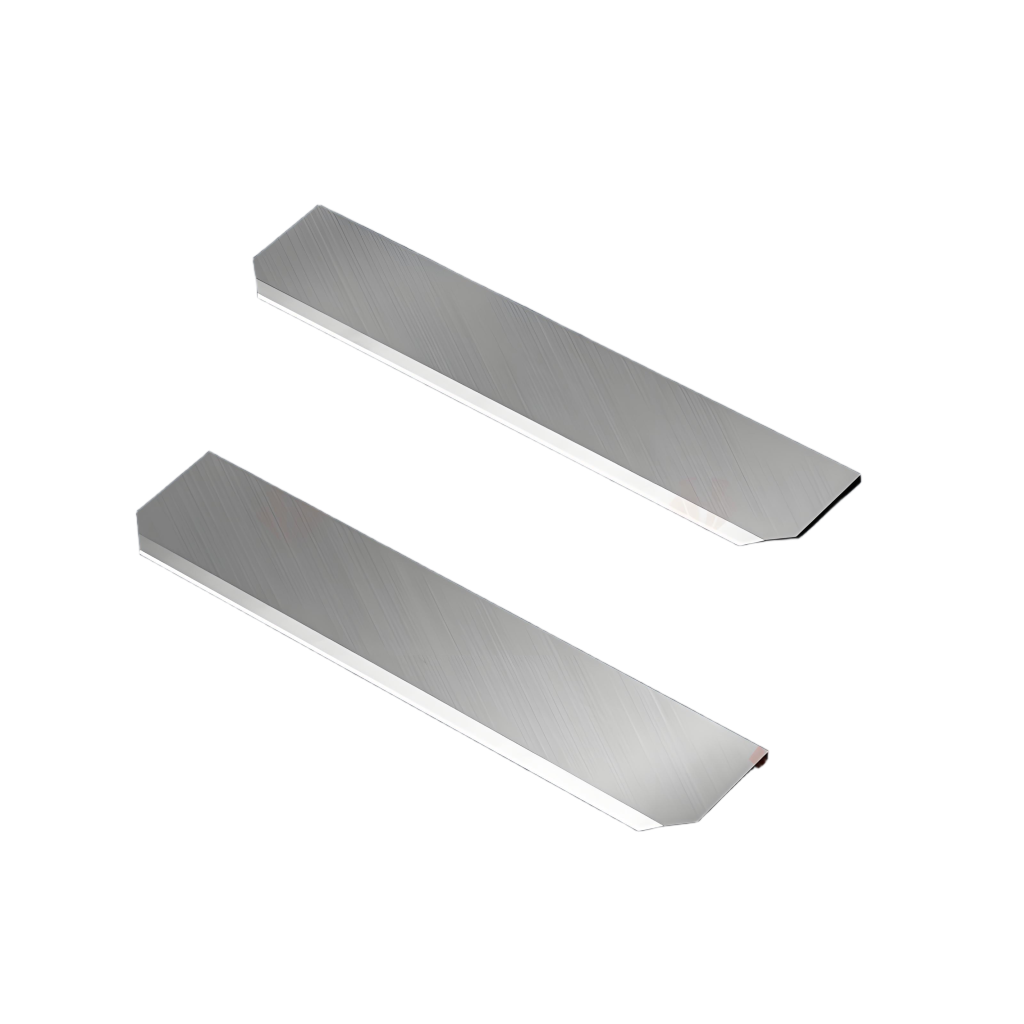

Film Slitting Blades We Manufacture

Film slitting blades for clean, high-speed cuts—edge geometry, grinding precision, and surface finish optimised to reduce dust, prevent edge tearing, and maintain consistent slitting performance over long runs.

Film slitting blades for clean, high-speed cuts—edge geometry, grinding precision, and surface finish optimised to reduce dust, prevent edge tearing, and maintain consistent slitting performance over long runs.

Film and flexible materials are typically slit by razor slitting, shear slitting, or score/crush slitting. Each method drives different requirements for blade stiffness, edge geometry, and mounting stability.

For thin, flexible webs where fast changeover and clean separation are priorities.

These are the most frequent reasons film edges become unstable on the line—and where blade spec changes deliver clear gains:

Dust / angel hair / rough edges

Usually linked to edge wear progression, unstable engagement, or film structure abrasiveness.

Edge tearing or inconsistent slit line

Often caused by mismatch between slitting method and blade format, or insufficient mounting stability.

Fast dulling / short change intervals

Common with abrasive coatings, filled films, or adhesive contamination; may require coating + edge preparation changes.

Tracking sensitivity at speed

Thin-blade vibration or holder fit can amplify cut variation; stiffness and fit consistency become key.

To keep film slitting results stable across repeat orders, we control the factors that most directly affect edge quality and change intervals:

Do you have any questions about our products and how to use them? We have compiled the most frequently asked questions and answered them. If your question is not listed here, please contact us.

Start with your slitting method and holder design. Razor lines typically use slotted / 3-hole / injector formats, while shear and score/crush systems use top & bottom circular slitters and anvils.

Low-friction, wear-stable coating directions can reduce drag and heat buildup and help slow down wear—especially when adhesive transfer is part of the issue. We’ll recommend based on your film stack-up and run profile.

Yes. Send a drawing or a physical sample, plus photos of your holder or mounting area, and we’ll match the mounting details and edge specification.