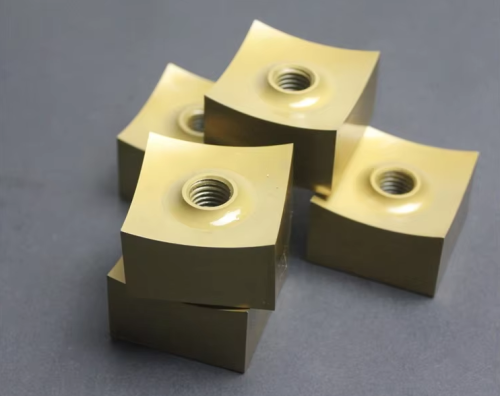

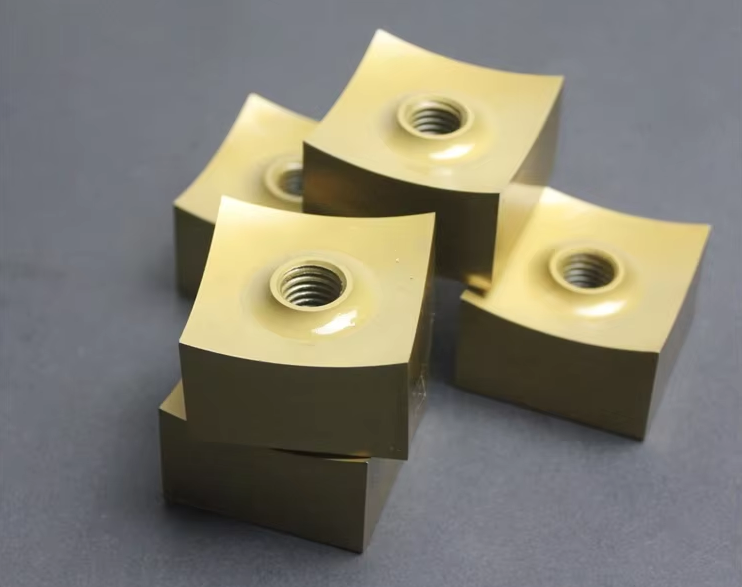

Crusher Blade: The Core Cutting Edge in Industrial Crushing

In numerous links of industrial production, material crushing is an extremely crucial step. Whether in mining, construction material processing, plastic recycling, biomass energy utilization and other industries, efficient and precise crushing operations directly affect production efficiency and product quality. Behind this, Crusher blade, as the core component of crushing equipment, plays an irreplaceable important role. Today, let's have an in-depth understanding of the Crusher blade produced by our company and see why it can stand out among many similar products.

I. Excellent Product Performance

- High Hardness and Wear Resistance: Our Crusher blades are made of high-quality high-alloy tough steel and ultra-fine grain super-hard alloy materials. These materials have been carefully selected and proportioned, endowing the blades with extremely high hardness, enabling them to easily withstand the impact and wear of various hard materials. In mining crushing, when facing extremely hard ores, our blades can still remain sharp, work continuously and stably, greatly extending the service life of the blades, reducing the frequency of equipment shutdown for blade replacement, and saving a lot of time and costs for enterprises.

- Precise Cutting Ability: The design of the blade has undergone precise calculation and optimization, and its edge shape and angle can ensure precise cutting of materials during the crushing process. Whether crushing large materials into small pieces or pulverizing materials into particles of specific sizes, our Crusher blade can complete the task excellently. In the plastic recycling industry, it is necessary to crush various plastic products into uniform small particles for subsequent processing. Our blades can accurately crush plastic products into the required particle size, ensuring the quality of recycled plastics and the smooth progress of subsequent processing.

- Strong Toughness: In addition to high hardness and wear resistance, the blade also has excellent toughness. This means that the blade is not prone to fracture or damage when facing high-intensity impact and vibration. In the processing of construction materials, when dealing with materials such as concrete and bricks, the equipment will generate a large impact force. Our Crusher blade, with its strong toughness, can withstand this impact, maintain structural integrity, and operate stably, providing a strong guarantee for the continuity of production.

II. Wide Range of Application Fields

- Mining: In the process of ore mining and processing, Crusher blades are used for primary and secondary crushing of mined raw ores. From hard iron ores, copper ores to various non-metallic ores, our blades can efficiently crush them into appropriate particle sizes for subsequent mineral processing, smelting and other processes. Its excellent performance can adapt to complex and variable ore properties and harsh working environments, and it is an indispensable important tool in mining production.

- Construction Materials: In the construction materials industry, whether producing cement, sand and gravel aggregates, or processing construction waste, crusher blades play a key role. In cement production, it is necessary to crush raw materials such as limestone and clay into small particles for grinding and firing. Our Crusher blade can quickly and evenly crush these raw materials, improve production efficiency, and ensure the quality of cement. In terms of construction waste treatment, the blade can crush waste concrete, bricks, wood, etc., to realize the recycling of resources, which meets the requirements of environmental protection and sustainable development.

- Plastic Recycling: With the continuous improvement of environmental awareness, the plastic recycling industry is booming. Our Crusher blade performs well in the field of plastic recycling, and can crush various waste plastics, such as PET bottles, PE films, PVC pipes, etc., into small pieces or particles, which is convenient for subsequent cleaning, granulation and reprocessing. By using our blades, plastic recycling enterprises can improve recycling efficiency, reduce production costs, and reduce environmental pollution.

- Biomass Energy: In the field of biomass energy, it is necessary to crush biomass raw materials such as straw, sawdust, and branches into appropriate sizes for combustion, fermentation and other treatments to produce biofuels or electricity. Our Crusher blade can easily handle these soft but high-fiber materials, crush them into uniform particles, improve the conversion efficiency of biomass energy, and provide strong support for the development of renewable energy.

III. Advanced Production Technology

- Strict Material Selection: In order to ensure the high-quality performance of Crusher blades, we strictly control the selection of materials. We cooperate with well-known domestic and foreign steel suppliers to carefully select high-quality steel that meets the standards. Each batch of raw materials undergoes strict quality inspection, including chemical composition analysis, hardness testing, metallographic structure inspection, etc. Only materials that pass all inspections can enter the production process, ensuring product quality from the source.

- Precise Processing and Manufacturing: We have advanced CNC processing equipment and an experienced technical team, capable of precision processing of blades. Each process from forging, turning, milling to grinding of the blade is operated in strict accordance with high-precision process standards. In the grinding process, advanced grinding machines and grinding processes are adopted to ensure that the flatness and sharpness of the blade edge reach the best state. At the same time, through digital control technology, the dimensional accuracy of the blade can be precisely controlled to ensure that each blade meets strict quality standards.

- Unique Heat Treatment Process: Heat treatment is a key link to improve the performance of Crusher blades. We adopt advanced vacuum heat treatment and deep cooling treatment processes to precisely heat treat the blades. Vacuum heat treatment can effectively avoid oxidation and decarburization of the blade during heating, ensuring the uniformity of the internal structure and mechanical properties of the blade. Deep cooling treatment further improves the hardness and wear resistance of the blade. By cooling the blade to an extremely low temperature, the residual austenite inside is transformed into martensite, thereby enhancing the overall performance of the blade. After the unique heat treatment process, our Crusher blade achieves a perfect balance in hardness, wear resistance and toughness.

IV. Personalized Customization Services

We are well aware that different industries and customers have different requirements for Crusher blades. Therefore, we provide personalized customization services, tailoring the most suitable blade solutions for customers according to their specific usage requirements and working conditions.

- Material Customization: According to the nature and hardness of the materials crushed by customers, we select the most suitable blade materials for them. If customers need to handle high-hardness and highly abrasive materials, we recommend using super-hard alloy materials; if customers have higher requirements for the toughness of the blade, we will choose appropriate high-alloy tough steel materials. Through reasonable material selection, we ensure that the blade can perform at its best in actual work.

- Size and Shape Customization: We can customize Crusher blades of various sizes and shapes according to customers' equipment specifications and crushing process requirements. Whether it is standard-sized blades or special-shaped blades, we can accurately produce them through advanced processing equipment and rich manufacturing experience. Customers only need to provide detailed drawings or technical requirements, and we can create customized blades that meet their needs.

- Performance Optimization Customization: According to customers' specific working environments and production requirements, we can optimize and customize the performance of the blades. For example, if the customer's equipment runs at a high speed, we can carry out special design and treatment on the blade to improve its stability and reliability under high-speed operation; if the customer has higher requirements for crushing efficiency, we can improve the crushing capacity of the blade by optimizing the edge design and cutting angle of the blade.

V. Perfect After-Sales Service

We are not only committed to providing customers with high-quality Crusher blade products, but also pay attention to providing customers with perfect after-sales service, so that customers have no worries.

- Technical Support: We have a professional technical team, ready to provide customers with technical consultation and support. After customers purchase blades, we can provide installation guidance, use training and other services to ensure that customers can correctly install and use the blades and give full play to their performance. If customers encounter any technical problems during use, our technical personnel will respond in a timely manner and provide solutions through telephone, email or on-site services.

- Fast Logistics and Distribution: We have established a perfect and fast logistics system, cooperating with a number of well-known logistics partners to ensure that products can be delivered to customers in the first time. Whether customers are located at home or abroad, we can deliver the blades in a timely manner through efficient logistics distribution to meet customers' production needs.

- After-Sales Return Visit: Regular after-sales return visits are made to customers to understand their usage and satisfaction with the products. Through return visits, we can collect customers' feedback and suggestions, and continuously improve the quality of our products and services. At the same time, according to the usage of customers, we will provide them with reasonable suggestions on blade maintenance and replacement, helping them extend the service life of the blades and reduce production costs.

Choosing our Crusher blade means choosing excellent product performance, wide application adaptability, advanced production technology, personalized customization services and perfect after-sales service. We will, as always, adhere to the business philosophy of "quality first, customer first", continue to innovate and make progress, and provide customers with better products and services. If you have any needs for crusher blades, please feel free to contact us. We look forward to cooperating with you to create a better future together!