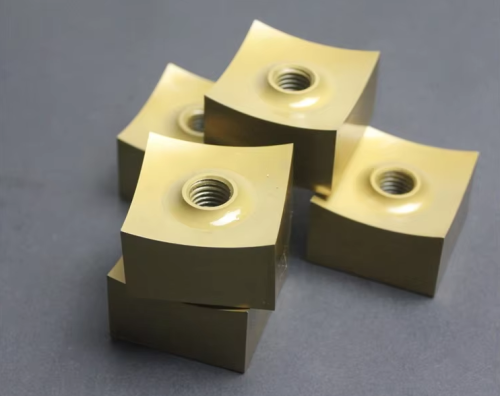

Packing Blade: The Precision Cutting Expert in the Packaging Industry

In the packaging production line, Packing Blade is the core component that determines cutting precision and efficiency. From the film slitting of food packaging to the edge cutting of carton packaging, a high-quality packing blade can directly improve product appearance and production efficiency, and our Packing Blade is designed for this purpose.

1. Precise Cutting, Defining Packaging Quality

Our Packing Blade is made of imported high-speed steel and alloy tool steel, and processed through multiple precision grinding processes, with the edge tolerance controlled within 0.01mm. Whether it is a food-grade composite film as thin as a cicada's wing or a corrugated cardboard as thick as 5mm, it can achieve smooth cutting without burrs or curling. In the field of pharmaceutical packaging, its mirror-polished edge can avoid secondary pollution of materials, fully meeting the GMP certification standards.

2. Wide Adaptability, Covering All Scenario Needs

From slitters and bag-making machines for flexible packaging to carton die-cutters and carton forming machines for rigid packaging, our blades can be adapted to more than 90% of mainstream equipment models at home and abroad. For different materials - plastic films, aluminum foils, kraft papers, composite materials, etc., there are more dedicated edge angle designs to ensure stable cutting performance even under high-speed operation, with a maximum linear speed of 600 meters per minute.

3. Customization Services, Solving Special Problems

We provide full-dimensional customization from material selection to edge shape. For packaging production in high-temperature environments, high-temperature resistant alloy materials can be used; for cutting viscous materials, Teflon coating treatment can effectively prevent sticking. Just provide the equipment model and material characteristics, and an exclusive solution can be provided within 72 hours.

4. Long-lasting Durability, Reducing Comprehensive Costs

Through vacuum quenching and deep cooling treatment, the blade hardness can reach HRC62-65, and the service life is 300% longer than ordinary products. Coupled with professional edge repair services, the performance remains unchanged after secondary grinding, greatly reducing the replacement frequency and procurement costs.

Choose our Packing Blade to make every cut a guarantee of quality. Contact us now to get free samples and adaptation plans, and let efficient production start from the "edge".